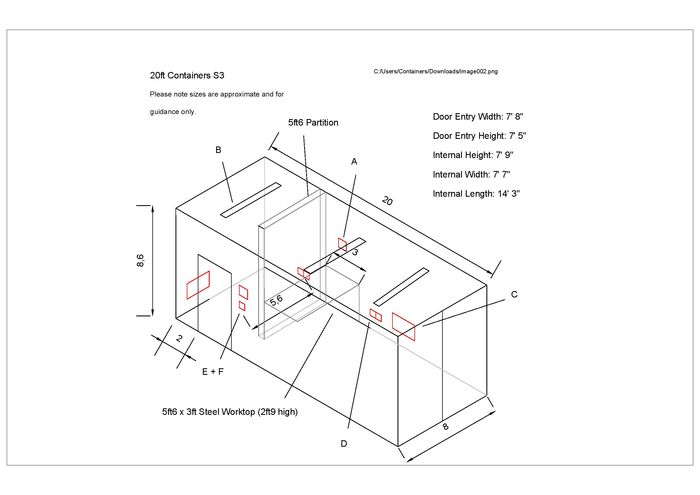

Shipping Container Conversions 20ft Workshop

CS22338

Pricing

*Call For Delivery Costs

CD Code CS22338

First we create the framework for the new door and cut an aperture into container. The frame is then welded into the aperture and a drip rail welded to the top, so the new door can be attached.

First a steel frame work is made using 50 by 50 box section. Then we weld this into the container, followed by 2mm thick steel sheets (cut to size on the guillotine), which fill the framework. The partition is 5ft 6" wide.

Once the partition was in place, we could fit the steel workbench behind it. 5ft 6" wide by 3ft deep, with a steel frame, this unit is perfect for heavy weight bearing.

Grafotherm is sprayed directly onto the ceiling of the container, to prevent condensation. Read how grafotherm works. Then we were able to paint over all the inside surfaces of the container, for a smart appearance.

The first step is to wire brush the container down, to achieve a smooth, clean surface to spray on a new coat of rubberised container paint.

Our client opted for our Electrical Package B:

And then it's off to the workshop!

Features

Design

Special Features

- Personnel door

- Internal partition

- Welded Durbar floor plate

- Grafotherm

- Steel workbench

- Metal extractor fan

- Fitted electrics

- S3 premium doors

Step 1 - Putting in the personnel door

First we create the framework for the new door and cut an aperture into container. The frame is then welded into the aperture and a drip rail welded to the top, so the new door can be attached.

More on personnel doors

Step 2 - Durbar floor plate

Durbar is a non-slip, raised pattern floor plate. As well as preventing slippage, it protects the timber floor of the container from spillages. The first task is to cut the durbar sheets to size on our guillotine. Then the plates are seam welded to the floor.

Step 3- Creating the partition

First a steel frame work is made using 50 by 50 box section. Then we weld this into the container, followed by 2mm thick steel sheets (cut to size on the guillotine), which fill the framework. The partition is 5ft 6" wide.

Step 4 - Heavy duty shelf

Once the partition was in place, we could fit the steel workbench behind it. 5ft 6" wide by 3ft deep, with a steel frame, this unit is perfect for heavy weight bearing.

Step 5 - Welding brackets for electrical installations

Step 6 - Grafotherm and interior painting

Grafotherm is sprayed directly onto the ceiling of the container, to prevent condensation. Read how grafotherm works. Then we were able to paint over all the inside surfaces of the container, for a smart appearance.

Step 7 - Fitting the extractor fan

Cutting the apeture

The extractor fan in place

Step 8 - Painting the container

The first step is to wire brush the container down, to achieve a smooth, clean surface to spray on a new coat of rubberised container paint.

Step 9 - Installing electrics

Our client opted for our Electrical Package B:

- Three x 5ft Strip Lights

- Two x Heaters

- Two x Double Sockets

- Wall Heater

- Consumer Unit

The finished product

It all starts with the CAD

And then it's off to the workshop!

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.