Shipping Container Conversions 8ft biomass energy unit

CS29382

Pricing

*Call For Delivery Costs

This conversion is for a Fre-engery, a company that specialises in turning organic waste into sustainable energy. Fre-energy builds anaerobic digestion systems as part of this process, and this container will be used to house the control unit for the digestion tanks.

CD Code CS29382

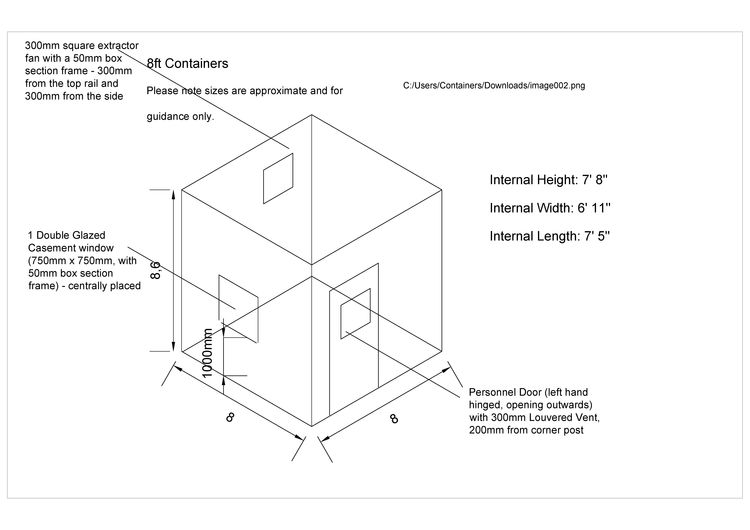

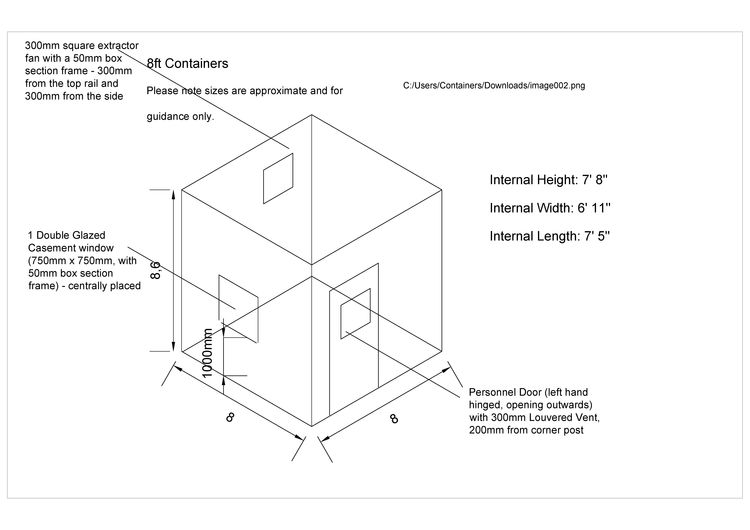

This container is being fitted with a personnel door, and requires no end doors, so first we need to blank the open end off by fitting a new wall. For full details of this process, see our article Shipping Container Wall Build

As an alternative to standard shipper container doors, our client has chosen a personnel door, designed specifically for frequent pedestrian access. The door has a large louvered vent fitted into it, to help cool the container.

We cut the correct sized aperture into the container wall, and made a steel frame to hold the window. The casement window (hinged at the side), has toughened glass and a trickle vent, to allow further ventilation.

First we cut and aperture into the container, and fitted a 50mm box section steel frame to hold the extractor fan. We made a grill and cowl to deflect rainwater. The fan will be thermostatically controlled.

We used fire retardant materials to insulate this container, and lined with 9mm redwood finish ply.

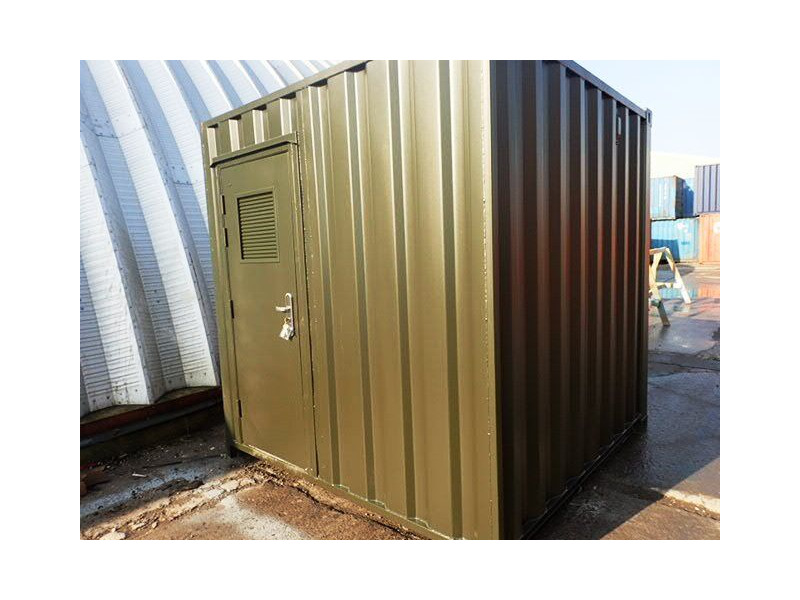

The container is repainted in Juniper Green, and is ready for delivery.

Features

Design

Special features

- 8ft once used container

- No end doors

- Personnel door with louvered vent

- Casement window with toughened glass

- Extractor fan with cowl

- Ply lined and fire retardant insulation

- Repainted Juniper Green

The CAD

Fit end wall

This container is being fitted with a personnel door, and requires no end doors, so first we need to blank the open end off by fitting a new wall. For full details of this process, see our article Shipping Container Wall Build

Personnel door

As an alternative to standard shipper container doors, our client has chosen a personnel door, designed specifically for frequent pedestrian access. The door has a large louvered vent fitted into it, to help cool the container.

Obscured window

We cut the correct sized aperture into the container wall, and made a steel frame to hold the window. The casement window (hinged at the side), has toughened glass and a trickle vent, to allow further ventilation.

Extractor fan

First we cut and aperture into the container, and fitted a 50mm box section steel frame to hold the extractor fan. We made a grill and cowl to deflect rainwater. The fan will be thermostatically controlled.

Ply lining

We used fire retardant materials to insulate this container, and lined with 9mm redwood finish ply.

The finished container

The container is repainted in Juniper Green, and is ready for delivery.

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.