Shipping Container Conversions 40ft ply lined, electrics, partitioned

CS25313

Pricing

*Call For Delivery Costs

Bridge 8 Hub is a social organisation in Edinburgh that has transformed overgrown wasteland alongside Scottish canals, using shipping containers, to offer outdoor activites to families and young people. They commissioned Containers Direct to fit out four 40ft shipping containers. These comprise of a meeting space, drying facilities, store room, bike shop, cafe and toilet/changing facilities. We feature one of the containers here.

CD Code CS25313

Before we can fit the personnel door and window, we have to cut the correct sized apertures into the required position in the container. With this this conversion these are in the end wall. We then create a frames, which we weld into the aperture, in order to attach the door and window.

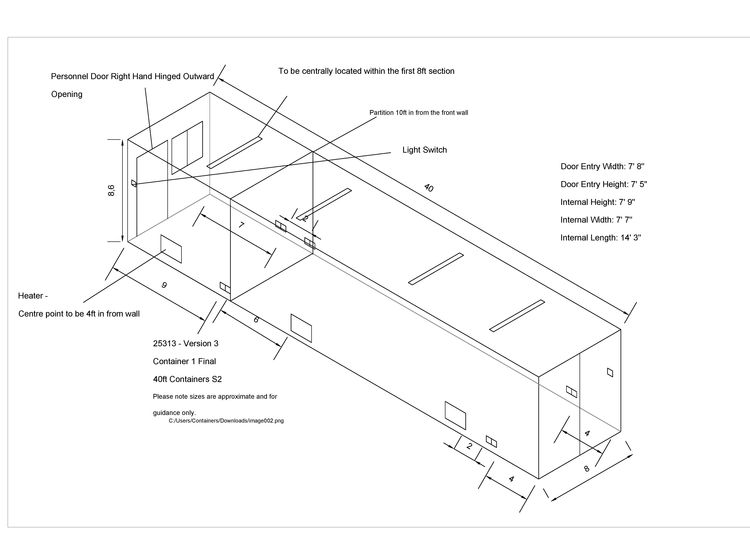

To create the partition we start by making a steel framework, which is then welded into position on the container and filled with steel sheets, cut to size using our guilllotine. The partition was placed 10ft in from the front wall, to give a 10ft section, and a 30ft section inside the container.

Our client requested our 9mm redwood option of ply lining - this gives a more attractive finish. We pack in rockwool insulating material behind the ply board frame. For detail information, see our page Ply Lined Containers

Features

Design

We used a good condition 40ft ISO container for this conversion. The original doors were retained and additional door and window fitted at the opposite end.

Conversion features

- Personnel door

- Window with anti-vandal shutters

- Ply lined and insulated

- Electrics

- Heating

- Internal partition

Fitting the personnel door and window

Before we can fit the personnel door and window, we have to cut the correct sized apertures into the required position in the container. With this this conversion these are in the end wall. We then create a frames, which we weld into the aperture, in order to attach the door and window.

The Partition

To create the partition we start by making a steel framework, which is then welded into position on the container and filled with steel sheets, cut to size using our guilllotine. The partition was placed 10ft in from the front wall, to give a 10ft section, and a 30ft section inside the container.

Back end of partition

Front end of partition

Ply lining and Electrics

Our client requested our 9mm redwood option of ply lining - this gives a more attractive finish. We pack in rockwool insulating material behind the ply board frame. For detail information, see our page Ply Lined Containers

The CAD

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.