Shipping Container Conversions 30ft tunnel, ply lined

CS31221

Pricing

*Call For Delivery Costs

This conversion is heading down to Cornwall, to be situated on the Hawksfield site, a complex containing unique and stylish home-ware, food and cafe units. The site will be using it as a storage unit, with a view to possibly converting it for use as another retail, or cafe in the future.

CD Code CS31221

Shipping containers mostly come in standard sizes of 20ft and 40ft, so to make anything smaller or inbetween, we have to cut down to the required size. with this job, we began by taking a standard 40ft shipping container and cutting off a 10ft sized piece from the front wall end, to create a 30ft container. As we are converting this container into a tunnel (doors at both ends), we then have to weld a "new" set of ISO doors to this open end.

The container already has its original doors, but we have to add another set to the opposite end. We take the ISO doors from another container, but first we have to manufacture a new frame to fit them into. When this step is complete we weld the frame with doors on, to complete the container.

The inside of the containers, including the doors, are ply lined and insulated with 12mm ply and rockwool. For more on this process, see our article Ply Lined Containers

The whole container is repainted green for an attractive finish.

Features

Design

Special Features

- Original container doors

- Additional set of double doors to create "tunnel"

- Ply lined and insulated

- Repainted

Making a 30ft container

Shipping containers mostly come in standard sizes of 20ft and 40ft, so to make anything smaller or inbetween, we have to cut down to the required size. with this job, we began by taking a standard 40ft shipping container and cutting off a 10ft sized piece from the front wall end, to create a 30ft container. As we are converting this container into a tunnel (doors at both ends), we then have to weld a "new" set of ISO doors to this open end.

Creating the "tunnel"

The container already has its original doors, but we have to add another set to the opposite end. We take the ISO doors from another container, but first we have to manufacture a new frame to fit them into. When this step is complete we weld the frame with doors on, to complete the container.

Ply lining

The inside of the containers, including the doors, are ply lined and insulated with 12mm ply and rockwool. For more on this process, see our article Ply Lined Containers

Repainting to finish

The whole container is repainted green for an attractive finish.

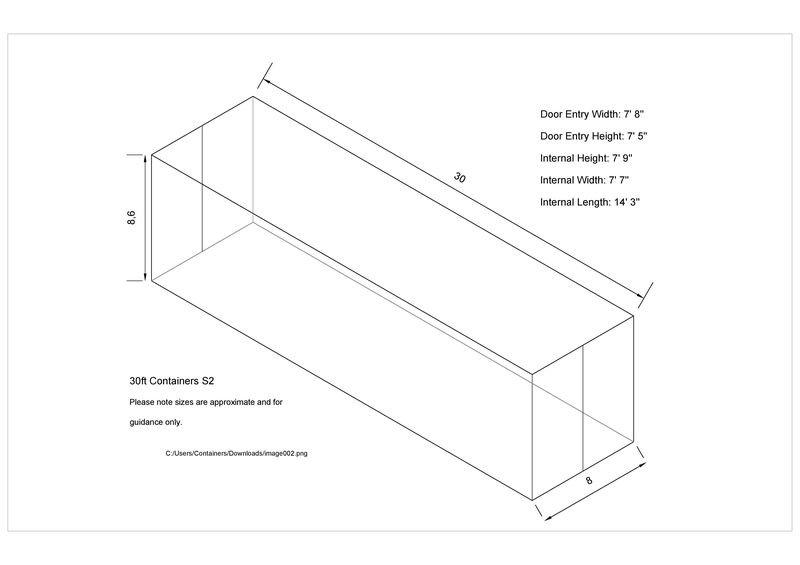

The CAD

As with any product, specification is subject to change without prior notification. You are advised to confirm current specification before buying.